产品中心

联系我们

微信:13952150662

手机:13952150662

电话:0516-87791695

Q Q:705209396

联系人:张经理

http://www.weightec.net/

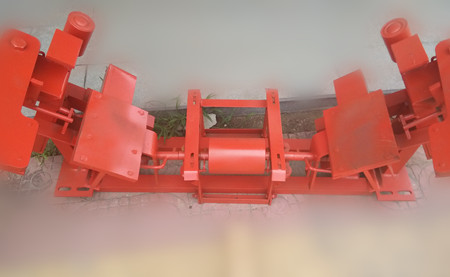

带式输送机用断带抓捕器Break arrestor

带式输送机用断带抓捕器:

带式输送机用段带抓捕器分上胶带断带抓捕器(WDDZ-S型)和下胶带断带抓捕器(WDDZ-X型)。正常情况下作托辊使用,当发生断带或逆止器失效时,可迅速抓捕住胶带突然下滑的重、空段胶带,并具有防止胶带跑偏的功能,在需要时可作卡带器使用。主要适用于向上运输的胶带输送机,特别适用于大倾角、大运量、长距离的上山强力型或普通型胶带输送机。

上胶带断带抓捕器(WDDZ-S型):

皮带输送机在正常运行时,断带抓捕器的上、下制动闸块和悬挂式可逆止托辊与皮带不接触。当发生断带时,载有物料的皮带下垂下滑,压在断带抓捕器的悬挂式可可逆止托辊和左、右两侧下制动平面闸块上,使其沿楔形轨道快速向上位移,逐渐缩小上、下制动闸块间的距离,最终将下滑皮带抓捕夹住。

下胶带断带抓捕器(WDDZ-X型):

皮带输送机在正常运行时,下层皮带与下闸块和偏心辊不接触。当发生断带时,装在上层胶带下方的动力臂受力下降,带动由连杆、弹簧、柱销组成的机构将偏心辊迅速释放,由于偏心辊胶带同向运行,使下制动闸块与偏心辊的间隙逐渐缩小,快速将胶带抓捕。

性能特点:

WDDZ系列皮带断带抓捕器左右两侧为400mm*160mm上、下制动闸块、中间 悬挂式可逆止托辊。当皮带发生断带时,其左右两侧的上、下闸块与悬挂式可逆止托辊同步联动抓捕皮带,受力均匀,制动距离短,不会造成撕裂皮带。

WDDZ系列皮带断带抓捕器安装调试后,其左右两侧的上、下制动闸块和悬挂可逆止托辊与运行皮带不接触,使用寿命长,不产生运行维修费用。

当运行中的皮带上有大的煤块、矸石通过时,制动臂能灵活转动,以便大块矸石、煤块通过,且自动复位。上制动闸块沿皮带横向、纵向可调以适应现场皮带两侧边缘无煤带的不同宽度。采用沿线多点布置,适应皮带断带点的随机变化,具有防跑偏、逆止器失效、断带报警多项保护功能。

使用范围:

带宽500~2000mm的带式输送机;刚性架式或吊挂式输送机;皮带输送机的倾角≥6°;适用于各种槽型托辊槽角

The belt grabber for the belt conveyor is divided into the belt breaker (type WDDZ-S) and the lower belt breaker (type WDDZ-X). Normally used as a roller, when the belt break or reverse stop failure, can quickly catch the tape suddenly sliding heavy, empty tape, and has the function of preventing tape deviation, can be used as a belt holder when needed. Mainly suitable for upward transport belt conveyor, especially for large inclination, large volume, long distance up the mountain strong type or ordinary type belt conveyor. Belt breaker (Type WDDZ-S): When the belt conveyor is in normal operation, the upper and lower brake blocks and the suspended reversible stop rollers of the broken belt catch are not in contact with the belt. When the broken belt occurs, the belt carrying the material sags and slips, which is pressed on the suspension reversible stop roller of the broken belt catch and the lower brake plane brake block of the left and right sides, so that it moves up quickly along the wedge track, gradually reduces the distance between the upper and lower brake blocks, and finally catches the sliding belt and clamps. lower tape breaker (type WDDZ-X): belt conveyor in normal operation, the lower belt and lower gate block and eccentric roll do not contact. When the belt break occurs, the force of the power arm installed under the upper tape decreases, driving the mechanism composed of connecting rod, spring and column pin to release the eccentric roll quickly. Because the eccentric roll tape runs in the same direction, the gap between the lower brake block and the eccentric roll is gradually reduced, and the tape is quickly captured. Performance characteristics: The left and right sides of WDDZ series belt breaker are 400 mm*160mm upper and lower brake blocks, middle suspension reversible stop rollers. When the belt breaks, the upper and lower gate blocks on the left and right sides of the belt and the suspended reversible stop roller synchronously catch the belt, the force is uniform, the braking distance is short, and the tear belt will not be caused. After the installation and debugging of the WDDZ series belt breaker, the upper and lower brake blocks and the suspension reversible stop rollers on the left and right sides of the belt are not in contact with the running belt, and the service life is long and no operating maintenance cost is generated. When the belt in operation has a large coal block, gangue through, the brake arm can be flexible rotation, so that large gangue, coal through, and automatic reset. The upper brake block can be adjusted horizontally and longitudinally along the belt to meet the different width of the coal-free belt on both sides of the belt. Adopting the multi-point arrangement along the line, adapting to the random change of the belt breaking point, it has the function of preventing running deviation, the failure of the reverse stop device and the multiple protection of the belt breaking alarm. Scope of use: Belt conveyor with bandwidth of 500~2000mm; rigid frame type or hanging type conveyor; inclination angle of belt conveyor ≥6°; suitable for all kinds of slot type idler slot angle